TVLogic's New Color Management LogiColor

LogiColor is newly developed Color Management System which achieve very correct, flexicible and stable color reproduction of TVLogic monitors.

We are proud to introduce the implementation of LogiColor, which is aiming for enhanced accuracy of color reproduction and constant color management at customers' site. It's not just a new firmware with improved functionalities, but an innovation inside the whole color processing pipeline to control monitor colors. It covers not only design and manufacture, but also customer support and useful information publication for customers.

Choice:

'LogiColor', the new color engine and the color management system features following items;

The whole-new sophisticated Color Processing

Now starting with the upgraded LUM-series monitors, TVLogic monitors are equipped with the whole-new color signal processing engine

in 24bit linear RGB color space. It achieves correct calculation and flexible support for various color standards, colors gamuts and EOTFs.

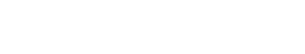

The whole-new intelligent Monitor Calibration

An innovative calibration method is introduced to TVLogic monitors, and the new calibration software (logiCAL) is also developed based on WonderLookPro's technology to perform the most accurate calibration process. This assures very accurate color reproduction for entire color space of the monitor. And a calibration report is created with all the detailed information and analysis of correct color reproduction.

The whole-new in-Display Color Management

In order to compensate the non-linearity of the display panels' color reproduction, a new processing method is introduced including the tetrahedral interpolation that is used in IS-mini series product to achieve correct and stable interpolation. Thanks to this new process, the monitor utilize full power of the LCD panel more than before.

The well-managed Factory Calibration

To ship our monitors in ideal condition, we have re-built the factory calibration procedures. Now the color measurement probes are upgraded with TVLogic's proprietary probe calibration method. And temperature control and perceptual color matching parameters are also introduced.

Customer beneficial Information Publication

We are planning to publish as much information as possible. It will help customers to find the best way to use our monitors in good condition and correct colors. Customers will be able to understand our monitor performance in detail and could even know the limitation of each product.

Providing easy method of Customer side calibration

We will provide our new calibration software free of charge to our customers. Simple instruction will help the customer to calibrate our monitors correctly. And the function of perceptual matching provide you the calibration to match your mastering monitor white, even with not so correct probe. The new monitor calibration software supports both Windows and MacOS, but Windows version will be released in Jun 2020 and the MacOS version will be released later in Q4 of 2020.

'LogiColor' engine is first applied to current 4K monitors of LUM-series starting with LUM-310-CI.

The suffix of 'CI' stands for 'Color Innovation' and imply that the new color engine (LogiColor) is equipped,

and the monitor is calibrated by the newly developed 'logiCAL' software and using probe profile created by the newly developed 'ProbeCAL' software.

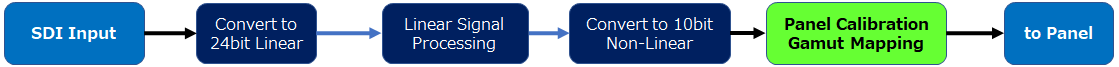

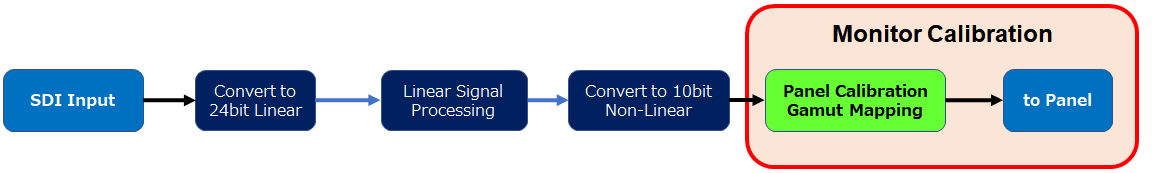

Signal Processing in Monitor

The monitor receives SDI signal or HDMI signal of the image in YCrCb or RGB values.

Most of the format uses 10bit for each channel.

The role of the signal processing in the monitor is to convert these values to feed to the LCD panel engine to achieve correct colors on the panel based on the settings give to the monitor.

Introducing HDR color spaces, the parameters affecting to colors are increased and complicated.

Monitos have to calculate the color values as correct as possible.

Here is the diagram which shows the steps of the process.

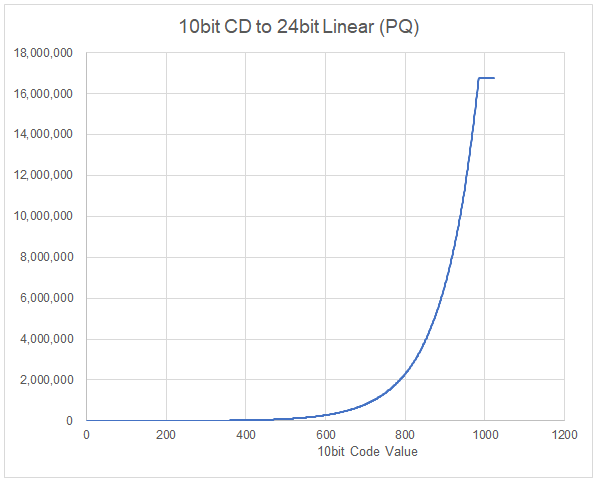

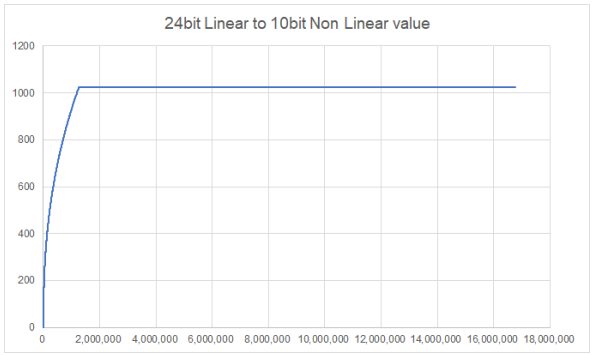

1. Convert to 24bit Linear

All of the colors input to the monitor, after converted to 10bit RGB, are converted to 24bit linear values by the selected EOTF function.

The minimum digit means 0.00097656 nits. Maximum value is 16384nits.

It was processed by the full length of 1DLUT, so there would no errors and it is easy to increase the kind of EOTF.

We will add wide varieties of camera LOG gamma's in near future.

2. Linear Signal Processing

The first process of linear signal processing is to apply matrix decided by the color gamut and white point.

Now that, we have a completely color space independent linear signal values.

The signal was applied gain and offset parameters here.

3. Convert to 10bit Non-Linear Signal

This is the process to convert to 10bit non-linear signal again, which is suitable to apply panel calibration process.

Maximum value 1023 meaning is different to monitor to monitor.

For the 1000nits monitor LUM-310X, 1023 is equivalent to 1600nits.

Converting 24bit linear to 10bit non linear signal is not so each on the limited capability hardware.

We developed sophisticated method to achieve this even on the rather limited capability of the hardware, which means it can apply old type of monitors.

4. Panel Calibration and Gamut Mapping

The role of the last process is to create suitable 10bit code values to be feed to the panel engine.

This process have to compensate the errors of the panel and the limitation of the color reproduction of the panel.

We call "calibration" to reduce the error of the panel, and "gamut mapping" to find the substitution color

from outside of the panel gamut to the inside gamut.

For the calibration, we developed the new algorithm to achieve correct color reproduction throughout the monitor gamut.

And about the gamut mapping, we introduced hue preserving gamut mapping method.

Both algorithm are based on the algorithm of WonderLookPro, and refined to be used in the monitor signal processing.

The new software "logiCal" is taking care of all of this process and upload parameters including 3DLUT to the monitor.

Sophisticated Monitor Calibration Algorithm

We introduced new calibration algorithm to control LCD panel colors with ultimate accuracy.

The basics of this algorithm was developed for our software WonderLookPro, and the algorithm was renowned targeting for TVLogic monitors.

This is the last process of the signal processing chain in monitor.

Concept of Monitor Calibration

The role of the monitor calibration is to feed proper code value to the panel engine so that the aimed color will be shown on the panel.

The functions monitor calibration have to be included are,

1. Converting universal internal color space to the panel color space

2. Compensating non-linear component of the panel color space

3. Replacing the color which can not be reproduce on the panel to alternative color which can reproduce on the panel (mapping)

4. Compensating panel's unit to unit variation

5. Compensating panel's deterioration (especially important for aged monitors)

2. Compensating non-linear component of the panel color space

3. Replacing the color which can not be reproduce on the panel to alternative color which can reproduce on the panel (mapping)

4. Compensating panel's unit to unit variation

5. Compensating panel's deterioration (especially important for aged monitors)

Because 4 and 5 are different to unit to unit, we will do calibration for all of the monitors we are going to ship to the customers.

And also we recommend to the customer to calibrate the monitor regularly because of the reason 5.

The Method to do Monitor Calibration

To create monitor calibration transform which contains all of the 1 to 5 items, we measure each monitor for more than 300 colors to make correct model of the specific monitor.

After that we create the transform which converts internal non-linear value to proper panel value and wrote this transform information to each monitor.

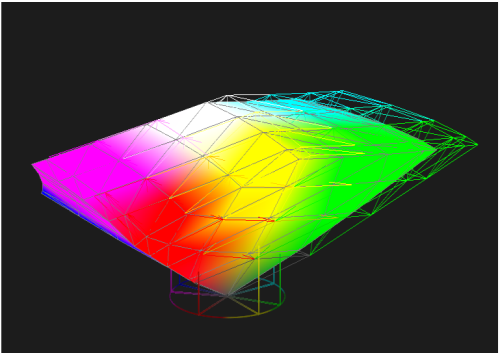

Here is the example of the monitor profile which was made by the measurement.

The color space is L*a*b*. Colored surface object is the monitor's gamut, the area in which monitor can reproduce colors.

This profile contains 1,2,4 and 5 variations.

Wired objects are the target color space, which is usually Rec2020/1000nits.

The colors belongs in the monitor's gamut objects are correctly calculated to reproduce correct colors on the panel.

In other words, the transformation created by this profile can compensate above 1,2,4 and 5 variations.

How we are treating colors outside of the Monitor's capability

But all of the current monitor's gamut is unfortunately less than the targeted Rec2020/1000nits gamut so there exists colors which can not be reproduce by the monitor.

These colors lies outside of the surface objects and in the wired objects.

These colors, which are called outside gamut colors, can not reproduce correct colors on the monitor anyhow,

but we have to avoid bad effect by these colors, to bring incorrect impression of the image, to make users wrong decision or wrong correction.

Facing to this problem, our solution's are

1. Gamut Mapping: Introduce sophisticated gamut mapping which keep color hue

2. Gamut Warning: Providing easy method to confirm outside gamut colors

3. Native Mode: Providing easy method to confirm entire image information discarding color accuracy

2. Gamut Warning: Providing easy method to confirm outside gamut colors

3. Native Mode: Providing easy method to confirm entire image information discarding color accuracy

1. Gamut Mapping

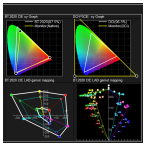

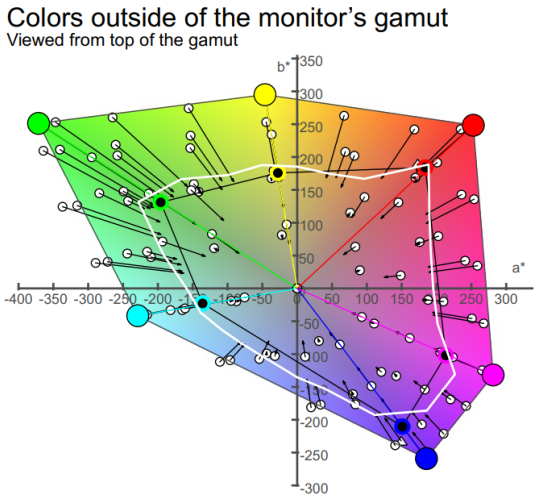

Here is the graph to explain one aspect of the gamut mapping.

The graph is the view of the L*a*b* color space from above, white side.

Indifferent of the brightness, colors can be represent in the plain by the hue and saturation.

The center is the neutral, gray, white or black.

Angle from the center represents hue and the distance represents color saturation, outer the more saturated.

Background colored area is the entire color gamut of Rec2020/1000nits color space, which would be feed to the monitor,

and white closed line shape is the maximum gamut area this monitor can reproduce.

All of the colors will be reproduced in this area.

Gamut mapping algorithm will control the position of the color which lies outside of the gamut of the monitor.

White small circles are the colors which is outside of the gamut, and the top of the allow of each of them is the place of alternative

color which is inside of the monitor gamut.

Gamut mapping function will replace outside gamut colors with inside gamut colors.

As you can see, all of the arrows are heading to the center.

It means, before and after the mapping, no due change had happened.

Even the saturation was decreased to map into the monitor gamut, hue is preserved to keep the impression of the colors as close as possible to the original targeted color.

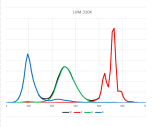

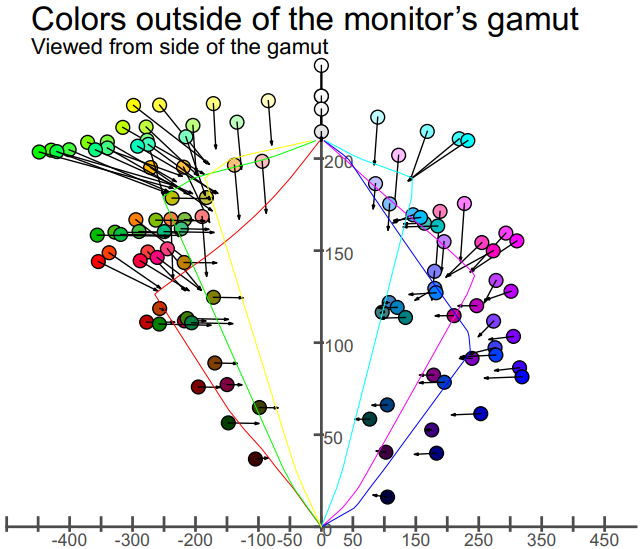

Here is the different view of the gamut mapping. The color space L*a*b* was observed from the side of it, and multiple direction view was overlapped.

Red and Cyan, Green and Magenta and Blue and yellow, in total three plane are drawn in the same graph.

Center vertical line is the gray line, starting from black at the bottom to white at the top.

Holizontal axis represents saturation, center is neutral, and both side, left and right direction means increase of the saturation.

You can observe thin color line, which consists triangle with the center gray line.

There are red, green blue, cyan, blue, magenta ones.

Each triangle means monitors gamut in each color hue plane.

Which means, the colors in the triangle is within the gamut of the monitor, and the colors outside of the triangle in the same plane

are outside gamut colors of the monitor, which can not be reproduced by the monitor.

Those outside of the gamut colors are shown in small circle with each colors.

You can find the arrow from the circle, which are heading various directions.

These are showing how the outside gamut colors are mapped into the inside gamut of the monitor.

All of the mapping happens in the same color hue plane, but the amount of the decrease of the saturation(toward the center vertical line),

or the decrease of the brightness(toward downside) is different from color to color.

But firstly, you can find the top of the arrow lies close to the side of the similar color triangle (there might not be the same hue plane).

This represents the mapping is performed to find the alternative color on the surface of the monitor gamut.

As you can easily understand, to do mapping, we have to decrease saturation and/or brightness.

Our mapping algorithm selects proper mapped places considering viewed impression and continuity of the colors.

2. Gamut Warning

The size of the gamut, how wide colors the monitor can represent, is different form monitor to monitor.

Some monitor might be very small, some monitor might be rather big.

When you are using the monitor in HDR mode or Rec2020 color space, some colors might be performed gamut mapping and might be reproduced different saturation or brightness.

You may want to know which colors are mapped to take care of these colors.

In such cases, we implemented gamut warning function, which can be called instantly by clicking function button.

Here is the example how the gamut warning result will be seen.

Just clicking the function button, you can switch warning on and off.

On left image, warning on, the outside gamut colors are labeled as extreme green colors.

You can check that high saturated colors are correctly reproduced or outside gamut, very bright colors which looks clipped might be outside of the gamut of the monitor.

By finding outside gamut colors by this function, you can adjust camera exposure, lighting or color correction.

3. Native Mode

Gamut warning is useful to tell the existence of the outside gamut colors, but can not tell the information of these colors

are kept in the signal or already lost before coming into the monitor.

To check the signal details, we provide to switch to native mode in a simple way.

Native mode is tentatively skipping all of the signal processing in the monitor to reflect all of the details in the signal

as the different color on the monitor.

Left image is under correct color space setting, and the right image is under native mode, all of the color process were skipped.

You can confirm all of the detail are kept in the original signal even these are outside of the monitor's gamut.

Instead of this benefit, all of the color correctness will be lost.

It can used only for the checking the existence of the information of the signal.

Calibration at the TVLogic factory

All of the assembled monitors at the TVLogic factory go through extensive color calibration and evaluation process to confirm the picture quality before shipment.

As we explained at the other article, monitor can not reproduce correct colors without correct environment and warming up process.

In addition, we are managing probes (color measurement devices) to achieve the best measurement accuracy.

1. Room Temperature

Monitor's stabilization is largely affected by the room temperature.

So we keep the room temperature of the calibration room to be 25˚C all the time.

The monitors brought into this room and turned on for stabilization for at least 3 hours before color calibration.

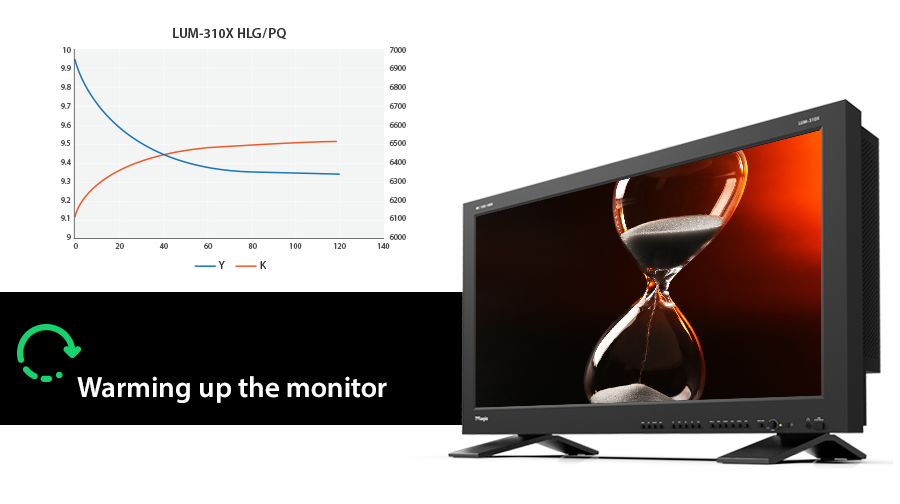

2. Warming up the monitor

Some of the recent monitors are capable of reproducing very bright colors.

But unfortunately, such monitors takes a long time to be stabilized after power on.

We decided the proper warming up time based on our aging test for each individual display panel.

LUM-310X needs the longest time for stabilization at this moment, that is 90 minutes.

Thanks to keeping enough warming up time, we can evaluate the monitor correctly after the calibration,

and customers are advised to use the TVLogic monitors under the same condition we calibrated.

All the stabilization data for the monitors with LogiColor engine will be provided on data sheet tab in product page.

LUM-310X-CI data Sheet --> http://www.tvlogic.tv/new/M_Spec2020.asp?sidx=111#tab06

LUM-310X-CI data Sheet --> http://www.tvlogic.tv/new/M_Spec2020.asp?sidx=111#tab06

3. Probe Management

We use a professional spectroradiometer of CS-2000A from KONICA MINOLTA as our master color measurement device.

We also use multiple units of colorimeters such as Klein's K-10As, ColorimetryResearch's CR-100

and Konica-Minolta's CA-210 for actual monitor calibration and customer service.

We create our own probe calibration profile for all of the K-10As for each type of monitors,

to reproduce exactly the same result with our master measurement device CS-2000A.

We use our own proprietary method to create probe calibration profiles instead of the conventional 4-color matrix method

provided by the probe manufacturers.

Based on the measurement of more than 80 colors instead of traditional 4-colors,

we achieved very accurate measurement of entire color gamut of monitors.

These profiles are updated every three months.

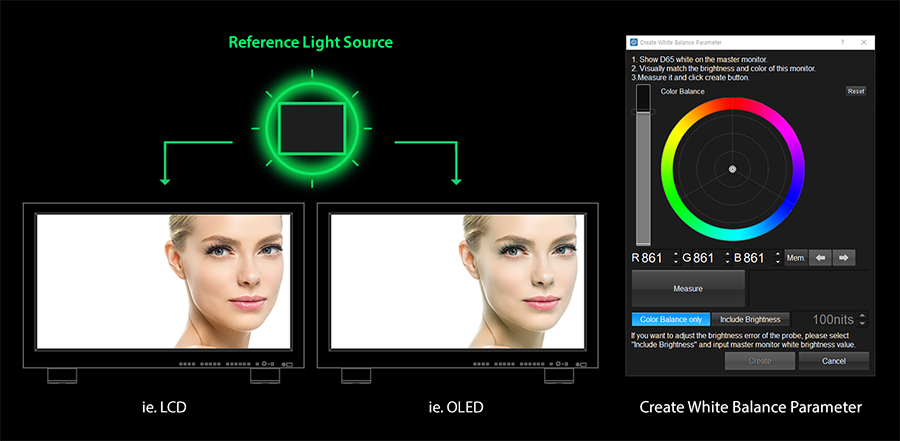

4. Perceptual Matching

Although we use a very accurate spectroradiometer as the master measurement device,

the same measured value for different types of monitor technologies do not always guarantee the same perceptual (or visual) colors.

This is brought by the incorrectness of CIE1931 XYZ spectral function and spectroradiometer residual errors.

So we introduced the method to remove the difference, and get the same visual colors for different type of monitors.

We use a pro-grade D65 light source as the reference white color, and create parameters for all types of

TVlogic monitors to visually match to the reference white color. And this parameters are used for monitor calibration at the factory.

By introducing this method, we calibrate the monitor not only very accurately, but also to be visually matched with true D65 white.

We are providing the similar function, the method to match customer's mastering monitor by using our new calibration software LogiCAL.

Customer can use monitor as factory calibrated status or, being matched with specific monitor by doing calibration by customer themselves.